Introduction

How long does it really take your company to go from “We need this” to “It’s here”?

If you don’t know, or if the answer is “too long”, you’re not alone. For many businesses, the procurement cycle time is a hidden drain on efficiency, cash flow, and supplier trust. What seems like a routine internal process can quietly cost your company thousands in delays, missed opportunities, and operational bottlenecks.

These days the supply chain environment, speed and agility in procurement are no longer optional, they’re a competitive necessity.

So, what exactly is procurement cycle time? Why does it matter so much? And more importantly, how can you make it work for your business instead of against it?

In this blog, we’ll break down the essentials, what procurement cycle time is, how to measure it, what slows it down, and actionable strategies to improve it using the right tools, supplier practices, and workflow designs.

TL;DR

- Understanding what procurement cycle time is and how it fits into the overall procurement life cycle.

- Exploring why procurement cycle time matters for cost savings, supplier performance, agility, and cash flow.

- Learning how to measure procurement cycle time using a simple formula and identifying the right data points.

- Identifying common bottlenecks that slow down procurement, such as manual approvals, communication gaps, and supplier delays.

- Discovering key strategies to reduce cycle time, including workflow automation, better supplier management, and ERP integration.

What is Procurement Cycle Time?

Procurement cycle time refers to the total duration it takes for a business to complete its procurement process, from the initial identification of a need to the final receipt of goods or services. It’s a critical performance metric that reflects how quickly and efficiently a company can move through its procurement life cycle.

The procurement cycle, also known as the procurement life cycle or simply the procurement process, is the step-by-step approach businesses follow to find, evaluate, acquire, and manage goods or services. It typically includes tasks like identifying requirements, sourcing suppliers, negotiating terms, creating purchase orders, and receiving deliveries.

The cycle time, therefore, is the clock that starts ticking the moment a requirement is raised and stops once the ordered item or service is successfully delivered and accepted.

Now that we’ve defined the term, it’s important to understand why procurement cycle time is a critical metric, and how it directly affects your business performance.

Also Read: Procurement Spend Management: Benefits and Effective Strategies

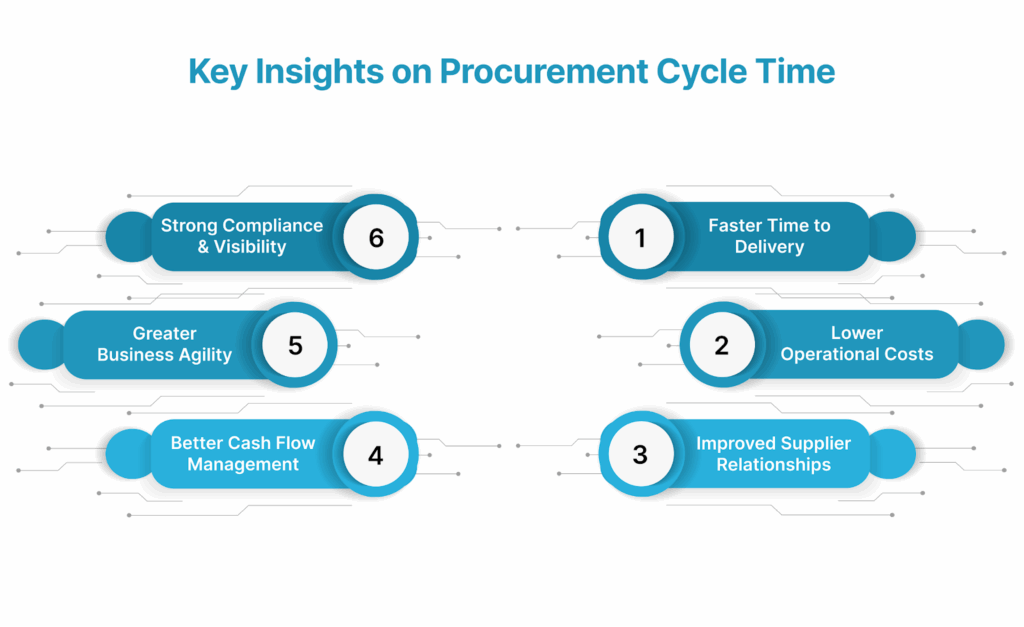

Key Insights on Procurement Cycle Time

Procurement cycle time is more than just a timing metric, it’s a reflection of how agile, efficient, and responsive your procurement operations truly are. Reducing this cycle can directly impact everything from cost savings and supplier performance to production timelines and customer satisfaction.

Here’s why it matters:

1. Faster Time to Delivery

A shorter procurement cycle means goods and services arrive sooner. This reduces the risk of production halts, project delays, or stockouts, especially critical in industries where timing is everything, such as manufacturing, retail, or healthcare.

2. Lower Operational Costs

Every extra day in the procurement cycle ties up working capital. Slow processes increase administrative overheads, delay invoice payments, and may result in expedited shipping fees or emergency purchases. Streamlining the cycle can significantly reduce these hidden costs.

3. Improved Supplier Relationships

When your procurement process is predictable and timely, it builds trust with suppliers. Vendors are more likely to prioritize your orders, offer favorable terms, and collaborate on long-term improvements when they experience consistent communication and order processing.

4. Better Cash Flow Management

Procurement delays often lead to delayed payments, budget overruns, or poor forecasting. Reducing cycle time improves visibility into upcoming expenses, enabling finance teams to manage cash flow more accurately and avoid last-minute financial surprises.

5. Greater Business Agility

In volatile market conditions, businesses need to respond fast. Whether sourcing from a new vendor due to disruption or launching a product quickly, a lean procurement cycle gives companies the flexibility to adapt without procedural bottlenecks.

6. Stronger Compliance and Visibility

A well-managed cycle allows procurement teams to track every step, maintain audit trails, and identify inefficiencies or compliance issues early. This visibility also supports better reporting and continuous process improvement.

Understanding its impact is one part of the equation. The next step is learning how to accurately measure procurement cycle time across your organization.

Also Read: Top 15 Procurement Tools for Businesses in 2025

How to Measure Procurement Cycle Time?

Measuring procurement cycle time is essential for identifying inefficiencies, benchmarking performance, and tracking improvements over time.

While the exact process may vary depending on the organization’s structure and procurement tools, the core idea remains the same: track the time between the initial request and the final receipt of goods or services.

At its most basic, procurement cycle time can be calculated using the following formula:

Procurement Cycle Time = Delivery Date – Requisition Date

- Requisition Date: When the purchase request is formally raised and submitted.

- Delivery Date: When the goods/services are received and verified by the buyer.

This formula provides a clear timeline of how long the full procurement process takes for a specific purchase. You can average this time across multiple transactions to calculate cycle time for specific departments, suppliers, or product categories.

Once you’ve measured your cycle time, the natural question is, what’s causing delays? Let’s look at the most common bottlenecks that inflate procurement timelines.

Also Read: A Step-by-Step Guide on How to Conduct a Category Analysis

Common Bottlenecks Slowing Down Cycle Time

Even the most well-defined procurement process can be dragged down by hidden inefficiencies. These delays may seem small in isolation, but when multiplied across hundreds or thousands of transactions, they can significantly inflate your procurement cycle time and disrupt operations.

Here are the most common bottlenecks that slow down procurement cycles, and what causes them:

1. Manual Approval Workflows

One of the biggest culprits is manual or email-based approval chains. When requisitions and purchase orders require multiple layers of sign-off, often across departments, approvals can get stuck in inboxes or delayed by absent stakeholders.

Impact: Extended lead time, unclear ownership, inconsistent approvals.

Why it happens: Lack of workflow automation, overcomplicated approval hierarchies.

2. Poor Communication Between Teams

Procurement involves multiple functions, finance, operations, legal, and supply chain. If teams aren’t aligned or using disconnected tools, it leads to delays in requisition creation, clarification requests, or missed updates during the PO and delivery stages.

Impact: Slower handoffs, misunderstandings, repeated back-and-forth.

Why it happens: Siloed departments, no centralized communication channel.

3. Incomplete or Inaccurate Requisitions

When purchase requests lack detail, like unclear specifications, budget codes, or delivery timelines, they’re often sent back for clarification. This backtracking eats into procurement time.

Impact: Rework, wasted hours, delayed supplier engagement.

Why it happens: Lack of procurement training or templated forms for requestors.

4. Supplier Delays and Response Times

Slow vendor responses to RFQs, long lead times, or delivery issues can inflate the second half of the cycle. A single unresponsive supplier can delay an entire sourcing project.

Impact: Missed project timelines, inventory shortages.

Why it happens: No vendor performance tracking, limited supplier pool, lack of SLA enforcement.

5. Disconnected Systems and Manual Data Entry

Using spreadsheets or multiple unintegrated systems slows down everything, from creating POs to matching invoices. Manual entry not only wastes time but introduces errors that require rework.

Impact: Processing delays, duplicate efforts, higher error rates.

Why it happens: Legacy systems, lack of procurement digitization or ERP integration.

6. Payment and Invoice Processing Delays

Even after goods are delivered, payment can be delayed due to mismatched documentation or slow invoice approvals, especially when procurement and finance teams work on different platforms.

Impact: Missed early-payment discounts, strained supplier relationships.

Why it happens: Poor invoice matching processes, fragmented financial controls.

Identifying issues is only the beginning. Let’s explore actionable strategies to eliminate these bottlenecks and optimize the entire procurement cycle.

Also Read: ChatGPT Applications in Procurement: Essential Use Cases and Examples

Key Strategies to Optimize Procurement Cycle Time

Reducing procurement cycle time isn’t just about speeding things up, it’s about removing friction from the process without compromising on quality, compliance, or cost. The goal is to build a more agile, responsive, and coordinated procurement function that meets business needs efficiently.

Here are some proven strategies to help you optimize procurement cycle time:

1. Standardize and Automate Internal Workflows

Manual approvals and inconsistent request formats are major sources of delay. By standardizing requisition forms and automating the approval hierarchy, you can eliminate repetitive follow-ups and ensure quick turnarounds.

- Use automated workflow tools to assign approvers based on spend thresholds.

- Pre-define requisition templates to reduce errors and back-and-forth.

- Digitally track the approval process to identify where requests stall.

Result: Faster requisition-to-order cycle with fewer manual interventions.

2. Build a Prequalified Supplier Base

Vendor selection can be time-consuming, especially when done from scratch each time. A curated list of pre-vetted suppliers for key categories helps accelerate sourcing decisions and purchase orders.

- Maintain a supplier database with updated certifications, contact points, and pricing.

- Use blanket purchase agreements or catalogs for recurring purchases.

- Review supplier performance regularly to keep the list lean and reliable.

Result: Reduced sourcing time and improved supplier responsiveness.

3. Use Real-Time Communication with Stakeholders

Break down silos between procurement, finance, operations, and other teams by establishing a centralized platform for communication and collaboration.

- Use procurement software or shared dashboards for full process visibility.

- Encourage cross-functional input early in the procurement process.

- Set clear SLAs and roles to prevent bottlenecks caused by unclear ownership.

Result: Streamlined handoffs and fewer internal delays.

4. Use Procurement Analytics to Identify Delays

Tracking historical cycle time data helps you pinpoint where and why delays occur. Use procurement analytics tools to monitor average time spent on each stage, requisition, approval, PO creation, delivery, and payment.

- Generate cycle time reports by category, department, or supplier.

- Identify outliers and repeat issues (e.g., delays from specific approvers or vendors).

- Set baseline targets and measure performance monthly or quarterly.

Result: Data-driven decisions that improve efficiency over time.

5. Integrate Procurement with ERP and Finance Systems

Disparate systems slow down the flow of information and lead to duplicate data entry. Integration helps procurement and finance work from the same set of real-time data for requisitions, orders, receipts, and payments.

- Sync procurement software with your ERP for faster PO and invoice processing.

- Enable 3-way matching to reduce payment delays.

- Consolidate reporting to track budgets, inventory, and supplier performance in one place.

Result: Fewer errors, faster processing, and better alignment across functions.

6. Create Clear Procurement Policies and Training

Inconsistent procurement practices, especially in large or growing organizations, lead to unnecessary delays. Having clear policies and well-trained requestors and approvers ensures that everyone follows the same efficient process.

- Define rules for when to use catalogs, when to go for competitive bidding, and when approvals are required.

- Provide onboarding and refresher training for all stakeholders.

- Offer self-service procurement portals for low-risk purchases.

Result: Fewer bottlenecks caused by confusion or policy deviations.

7. Adopt Scenario Planning for Risk Management

Supply chain disruptions can instantly extend cycle time. Use scenario modeling tools to prepare for supplier delays, demand surges, or geopolitical risks.

- Identify high-risk categories and map alternate sourcing strategies.

- Build buffer time into cycle expectations for complex items.

- Develop contingency supplier lists for key commodities.

Result: Greater resilience and continuity, even when the unexpected occurs.

By applying these strategies, organizations can reduce procurement cycle time without compromising governance or quality. The result is a faster, smarter procurement process that drives value, improves stakeholder satisfaction, and supports business agility.

akirolabs helps businesses significantly reduce procurement cycle time by turning complex, fragmented processes into a streamlined, strategic workflow. With AI-powered market intelligence, real-time scenario modeling, and centralized stakeholder collaboration, procurement teams can move from request to delivery faster and with greater confidence.

The platform brings together sourcing, approvals, data analysis, and ESG tracking in one place, eliminating delays, improving visibility, and supporting smarter, faster decision-making at every stage.

Book a demo today to see how akirolabs can help your team optimize procurement cycle time and elevate your sourcing strategy.

Conclusion

Procurement cycle time is more than just a metric, it’s a direct reflection of how efficiently your organization can respond to needs, manage suppliers, and support business goals. By identifying bottlenecks, standardizing workflows, utilizing real-time data, and aligning stakeholders, companies can significantly reduce delays and unlock faster, more strategic procurement operations.

An optimized cycle time leads to better cash flow, stronger supplier relationships, and a more agile response to market demands. Whether you’re scaling procurement in a growing organization or refining mature processes, focusing on cycle time is a smart, measurable way to drive value.

Ready to take control of your procurement cycle time? Book a personalized demo with akirolabs and discover how you can shorten delays, boost efficiency, and make smarter sourcing decisions, faster and with greater impact.

FAQs

1. How does procurement cycle time impact inventory management?

A longer procurement cycle time can lead to overstocking as businesses order goods earlier than needed to buffer delays, or understocking if lead times are underestimated. Optimizing the cycle time improves inventory planning, reduces carrying costs, and minimizes stockouts.

2. Can procurement cycle time vary between direct and indirect procurement?

Yes, it can. Direct procurement (materials tied to production) often involves more complex sourcing and stricter timelines, which may lengthen the cycle. Indirect procurement (office supplies, services) usually has a shorter, more repeatable cycle, especially with catalogs and pre-negotiated vendors.

3. What role does supplier onboarding play in reducing procurement cycle time?

Efficient supplier onboarding, collecting certifications, banking details, compliance data, ensures vendors are ready to receive orders without delays. A slow or manual onboarding process can delay sourcing, contract finalization, and the entire procurement cycle.